Rolled products

Rolled products

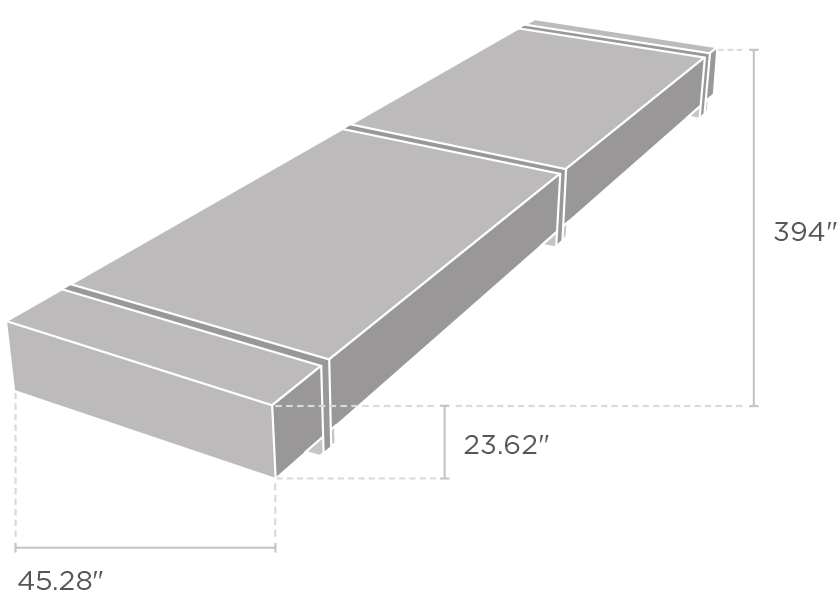

Rolled products, in the form of sheet ingots, account for 12 per cent of EGA’s total production output. The casting technology used at EGA is the state-of-the-art Low Head Composite (“LHC”) process that produces ingots of exceptionally high standard with a superior surface quality, resulting in significant savings for customers in downstream scalping and edge-trimming operations. EGA sheet ingots are available in a range of sizes and in lengths up to 394 inches.

The major proportion of EGA sheet ingots is supplied to most major European rolling mills and the balance to other global consumers. Predominant usage is in the packaging industry (including foil rolled down to 0.2 mm thick) and for lithographic plates used in printing. EGA sheet ingots are also suitable for the growing market in automotive applications where the low density of aluminium makes vehicles considerably more fuel-efficient and better for the environment. EGA also produces for applications such as can end and can body, where slabs are rolled down to microns.

Purities

Alloy series 1xxx, 3xxx, 5xxx, 8xxx.

Packaging

Packed in plastic-strapped bundles on wooden runners for convenient fork-lift handling.

Shapes/Forms

Weight

Weight depends on the dimensions

Dimensions

394” x 45.28” to 86.60” x 23.62”

(length x width x thickness)

Rolled products

EGA rolled products are available up to 394” long and from 45.28” to 86.60” in width.