Billets

Billets

Billets make up 46 per cent of EGA’s total production. Produced using Airslip technology, all billets are homogenized and 100 per cent ultrasound-inspected before delivery. Inherently superior in quality and intrinsic purity, a large proportion of the annual production is cast in high extrudability alloys. EGA’s products are supplied for construction (windows and door frames), transportation, engineering, consumer durables, automotive, forging, as well as many other applications. Several famous landmarks incorporate EGA’s aluminium products, such as Malaysia’s Petronas Towers, Dubai’s Burj Al Arab and Dubai Metro.

EGA’s extrusion billets have been declared suitable for sustainable building practices, as per the criteria defined by the US Green Building Council’s Leadership in Energy and Environmental Design (LEED) rating system and the Deutsche Gesellschaft für Nachhaltiges Bauen (DGNB, the German Sustainable Building Council).

Alloys

Produced in common AA alloy series 1000, 3000 and 6000 to customer specifications.

Packaging

Packed in steel- or plastic-strapped bundles on wooden runners for convenient fork-lift handling.

Shapes/Forms

DIAMETERS

6”, 7”, 8”, 9”, 10”, 11”,

12”, 14”, 15” and 16”

DIAMETER TOLERANCE

± 0,004”.

BILLET CUT LENGTH

16.5” to 295”.

CUT LENGTH TOLERANCES

16.5” to 78.74”: ± 0.12”

78.75” to 295”: ± 0.39”

BOW TOLERANCES

0.08” per 39” length of a log

0.47” for overall length of a log

SQUARENESS OF CUT

0.044” per 3.94” of the diameter; or 0.5° maximum deviation

Billets

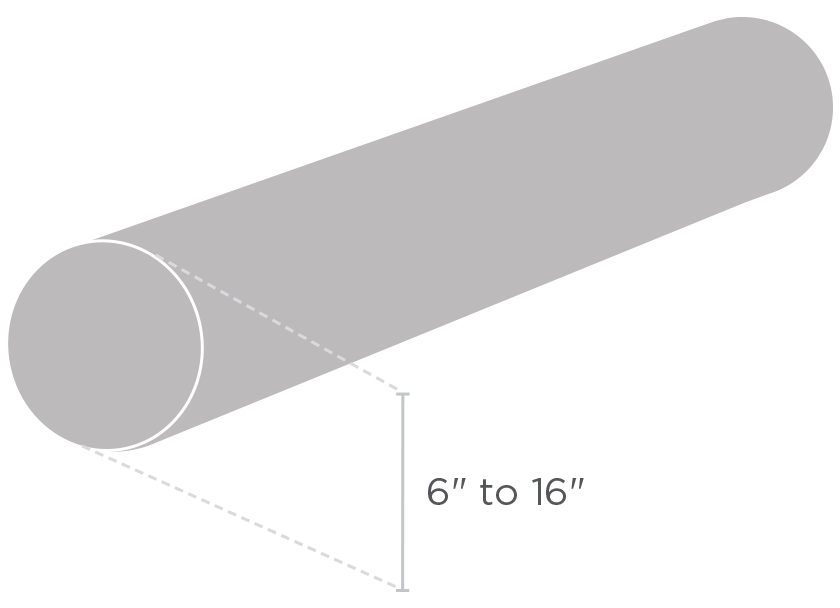

EGA's billets are cut from 16.5" - 295" in length and are available in diameters from 6" to 16".